.pdf+-+SumatraPDF_2012-12-12_01-49-34.png)

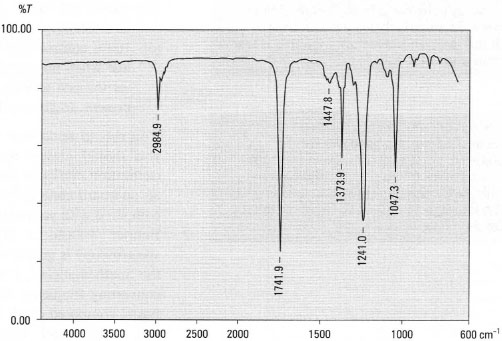

The rates of cure of bisphenol A based epoxy resin and its mixtures with diethylene glycol based epoxy resin with maleic anhydride and BF 3 etherate accelerator were measured from the dependences of degree of cure with time, using GPC, DSC and IR spectroscopy. Physical miscibility at ambient and chemical interactions at elevated temperatures between a difunctional epoxy of DGEBA and a linear phenyl-hydroxyl containing polymer, poly (4-vinylphenol), were investigated by DSC, FT-IR, SEM and solid-state 13C-NMR. New epoxide and cyanate ester resins with an aromatic ester backbone were synthesized and the intermediates were characterized by IR, 1H/ 13C-NMR spectroscopic methods. The molar mass of polyamide block/graft copolymers was determined by size exclusion chromatography (SEC) techniques. High thermally stable epoxy resins, prepared from Schiff base monomer and polymer, were studied by IR, 1H-NMR, GPC, DSC, TGA spectral analyses. In recent years, attenuated total reflection infrared (ATR-IR) micro-spectroscopy has been applied. Both Raman and IR micro-spectroscopy have been used to map differences on polymer surfaces.

#Ether ir spectrum free#

Non-reactive probes, such as excimer-forming probes, viscosity-sensitive probes, fluorescence quenching probes, polarity probes, free volume probes, and dual probe-label, as well as other probes have been used to monitor the cure reactions.Ĭure reactions of the stoichiometric mixtures of diglycidyl ether of bisphenol A (DGEBA) and two very low molecular weight aliphatic polyether diamines (PED) were studied by using mid and near infrared (IR) spectroscopic techniques. Among them, fluorescence techniques using molecular probes as extrinsic fluorophores have been applied to monitor the crosslinking process of epoxy/aromatic amines as well as epoxy/aliphatic amines. Since the degree of crosslinking or the chemical conversion is related to the performance and properties of epoxy coatings, several methods have been used to monitor the crosslinking reactions of epoxy/amine resins. Įpoxy resins crosslinked with aliphatic or cycloaliphatic amines are extensively used in protective coating applications. Namely, development and modifications of newer epoxy resins, and their applications in manufacturing composites, coatings, adhesives, paints, varnishes, construction materials and some other advanced fields. The development of new epoxy resins has been carried out on two aspects of the epoxy resins. The amount of all the epoxy species was estimated from IR spectra to changes during the crosslinking kinetics of epichlorhydrin.Īmong the different resinous materials utilized in polymeric applications, epoxies exhibit excellent electrical properties, good adhesion to materials having polar groups, low curing temperature, shrinkage on curing, good impact resistance and moisture resistance. Mid IR spectral analysis was used to calculate the content of the epoxy groups as a function of crosslinking time and the crosslinking degree of resin. The decrease in the IR band intensity of epoxy groups at about 915 cm −1, as well as at about 3,056 cm −1, was observed due to process. As the crosslinking proceeded, the primary amine groups in polyamine adduct are converted to secondary and the tertiary amines.

Crosslinking reactions of the different stoichiometric mixtures of the unmodified GY250 epoxy resin with the aliphatic EH606 and the cycloaliphatic EH637 polyamine adducts were studied using mid FT-IR spectroscopic techniques. A new epoxy formulation based on the use of polyamine adducts as the hardeners was analyzed. The use of fast FT-IR spectroscopy as a sensitive method to estimate a change of the crosslinking kinetics of epoxy resin with polyamine adducts is described in this study.

0 kommentar(er)

0 kommentar(er)